Acid & Alkali Resistant Fireproof Anti Corrosion Fume Hood for Chemical Laboratory

Description

Basic Info.

| Model NO. | YC-1800A / YC-1800B / YC-1800C |

| Feature | Corrosion Resistance, Heat Resistant, Acid & Alkali Resistant, Fireproof, Explosion Proof |

| Hood Type | Standard |

| Color | Blue |

| Customized | Customized |

| Condition | New |

| Liner | Ceramic Fiber |

| Airflow | Ceramic Fiber |

| Baffle | Ceramic |

| Sash | Tempered Glass |

| Work Surface | Ceramic |

| Product Name | Lab Fume Hood |

| Transport Package | Standard Export Wooden Case Packing |

| Specification | 1800*1005*2400(mm) |

| Trademark | Ample |

| Origin | Chengdu, China |

| HS Code | 8414809090 |

| Production Capacity | 100 Set/Month |

Packaging & Delivery

Package Size 1900.00cm * 900.00cm * 2100.00cm Package Gross Weight 500.000kgProduct Description

1. Product DescriptionProduct features:

1. Easy to assemble; Anti-corrosion and high temperature resistance;2. Unique down return air, timely and effectively exhaust without residual;3. Special flow-equalized design makes the flow even without any blind angle;4. The internal visual range will not form condensate due to temperature difference, therefore no drip will form;5. The internal airflow direction is not affected by the volume of the exhaust air, thus will not cause turbulence;6. Low energy consumption, easy to operate;7. Has air compensation channel and connection, saves energy, comfortable;8. Drainage will not be limited by the height of the drain,since it has pump to lift the sewage;;

Product function:1. Exhaust waste gas;2. New air compensation;3. Inorganic exhaust gas purification;4. Sewage treatment function (Acid and alkali neutralization);5. All electrical and mechanical devices can start and stop independently;6. Purification system resistance monitoring: auto-alarm when the set value is exceeded;7. Purification system temperature monitoring: auto-alarm when the set value is exceeded, and automatically cut offthe outlet power;8. Auto-monitoring the level of acid, alkali and spray media;9. Manual add acid and alkali (via dosing pump);10. Manual discharge of sewage (via sewage pump) and cleaning of spray system (via spray pump);11. Auto-replenishment of tap-water (via feed-water valve);12. Provide safe power supply (including phase-out and phase-sequence protection, Emergency power cuts, Leakage protection,Main power control;13. Safe light source (including adjustable white and non-UV yellow LED lights), external isolate installation;14. Water shortage protection for sewage pump and spray pump; 15. Overheat protection for mechanical andelectrical equipment;16. Alarm when sliding door in extra high position;17. The exhaust air volume is controlled by electric regulating valve;18. Other functions: water supply terminal, gas supply terminal and other experimental equipment can be installed according tocustomers' demands.2. Product Parameters

| Model Specification | WJ-1500A | WJ-1500B | WJ-1800A | WJ-1800B |

| External dimensions of equipment(mm) | 1500(W)*1205 (D) *2400 (H) | 1800(W)*1205 (D) *2400 (H) | ||

| Dimension of works pace (mm) | 1260(W1)*780(D1) *1100 (H1) | 1560(W1)*780(D1) *1100 (H1) | ||

| Panel material | 20+6mm thick butterfly ceramics | |||

| Material of internal lining board | 5mm thick ceramic fiber board | |||

| Diversion structure | Lower air return | |||

| Control system | Button control panel (LCD panel) | |||

| PH value control | The medium is alkaline water solution; manual monitoring, and manual control through acid pump and alkali pump. | |||

| Input power | Three-phase five-wire 380V/50A | |||

| Current for air fan | Not over 2.8A(380V or 220V can be directly connected) | |||

| Maximum load of socket | 12 KW(total of 4 sockets) | |||

| Water tap | 1 set (remote control valve + water nozzle) | No | 1 set (remote control valve + water nozzle) | No |

| Water discharge way | Magnetic chemical pump strong discharge | |||

| Using environment | For non-explosion indoor use, within 0-40 degrees Celsius. | |||

| Applicable fields | Inorganic chemistry experiment; Food, medicine, electronics, environment, metallurgy, mining, etc. | |||

| Ways of Purification | Spray sodium hydroxide solution, no less than 8 cubic meters/hour | Spray sodium hydroxide solution.no less than 12 cubic meters/ hour | ||

| Ways of surface air speed control | Manual control (through the electric air valve to adjust the exhaust air volume or adjust the height of the moving door) | |||

| Average surface air speed | 0.6-0.8 m/s Exhaust air volume: 1420-1890m3/h (when door height h =500mm) | 0.6-0.8 m/s Exhaust air volume: 1760-2340m3/h (when door height h =500mm) | ||

| Speed deviation of surface air | Not higher than 10% | |||

| The average intensity of illumination | Not less than 700 Lux; Standard white and uv-free yellow LED lamps; The illumination is adjustable. | |||

| Noise | Within 55 decibels | |||

| Flow display | White smoke can pass through the exhaust outlet, no overflow. | |||

| Safety inspection | No spikes, edges; Charged body and the exposed metal resistance is greater than 2 mQ; Under 1500V voltage, no breakdown or flashover occurred for 1min test. | |||

| Resistance of exhaust cabinet | Less than 160 pa | |||

| Power consumption | Less than 1.0kw/h (excluding power consumption of fans and external instruments) | Less than 1.2kw/h (excluding power consumption of fans and external instruments) | ||

| Water consumption | Less than 3.2L/ h | Less than 4.0L/ h | ||

| Performance of wind compensation | With a unique wind compensation structure, the volume of the wind will not cause turbulence in exhaust cabinet and will not directly blow to the staff (need to connect to the air compensation system of the laboratory) | |||

| Air volume regulating valve | 315mm diameter flanged type anti-corrosion electric air flow regulating valve (electric contact actuator) | |||

3. Type of Fume Hood

General Lab Use: Conventional hoods found on Purdue's campus and are approved for general chemistry, radioisotopes, and carcinogen or toxic chemical work.

High Performance: These fume hoods have containment-enhancing features allowing them to operate at lower face velocities while protecting the operator. Since less room air is exhausted, energy is conserved. REM will tag high performance hoods with a special standard operating procedure sticker, informing users of the appropriate air velocity range determined by the University.

Perchloric Acid: Special hoods equipped with a stainless steel or PVC duct and properly timed water wash down system. The wash down system must be used following each use of the acid hood. Using perchloric acid in a general lab fume hood may cause the acid vapors to settle onto the ductwork and create explosive perchlorate crystals. Serious injury or fatality may result to hood users or maintenance staff if the acid crystals are exposed to vibration and detonate.

Polypropylene (Acid Resistant): Dilute acids may be used at room temperature in most fume hoods, but if you are performing acid digestion, heating, or working with concentrated acids such as: HF, Aqua Regia, Nitric Acid, Piranha Solutions, etc., acid resistant hood and ductwork is required. Strong acids are corrosive to the duct work found in general lab fume hoods. Fume hoods constructed from polypropylene material are long-lasting and designed to resist harsh chemicals for years.

Walk-In: Equipped with a floor-mounted design, walk-in hoods specialize in exhausting chemicals that are used alongside large laboratory equipment. When using a walk-in hood, close the bottom sash to the floor and only raise the top sash to REM's designated working height. Do not obstruct the area at the face of the hood.

Ductless Filtered: Designed to remove potential hazardous fumes and vapors from the work area as the exhausted air passes through absorbent material, such as activated charcoal. Occasionally, the REM department is asked to approve purchases of ductless, filtered fume hoods for use in research labs. We do not recommend ductless fume hoods. We do not believe ductless fume hoods provide reliable protection against chemical exposure, and think they may, in fact, give workers a false sense of security.4. Detailed Photos

5. FAQ

The process of researching and purchasing the right fume hood for your laboratory can seem overwhelming and choosing the right one is crucial to ensuring safety from dangerous chemicals and vapors in your lab.

Here are a few important questions and considerations to help you choose the right fume hood for your lab.

- What type of work are you conducting inside your fume hood

- Review your experiment methods and material lists.

- Document which chemicals, or solvents, you will be using and the concentration of each chemical

- Determine the evaporation rate of the chemicals.

- Chemical solvents evaporate at different rates and if not accounted for, can overwhelm the fume hood by evaporating at a rate too fast for the fume hood to ventilate

- Chemical solvents evaporate at different rates and if not accounted for, can overwhelm the fume hood by evaporating at a rate too fast for the fume hood to ventilate

- Review your experiment methods and material lists.

- What size lab hood do you need?

- Will you have equipment inside your laboratory fume hood?

- How large is the equipment?

- If your application involves extra-large equipment, such as drum containers, a walk-in fume hood might be appropriate.

- How many people will be working simultaneously under the fume hood?

- Depth - Consider buffer space.

- Perform your work at least 6 inches behind the sash to ensure a safety buffer zone is maintained.

- Height - Make sure your lab has ample height clearance for a larger bench top or floor mounted fume hood.

- How will fumes be filtered and exhausted?

- Duct or ductless

- A ducted fume hood connects to a remote blower of the facility HVAC system to safely remove noxious or dangerous chemicals from the work area.

- A ductless fume hood contains an integral blower, carbon filters to capture chemical vapors and, if required, HEPA/ULPA particle filters to allow recirculation of exhaust air.

- Duct or ductless

- Which ventilation system should you use for a ducted fume hood?

- A ducted fume hood has two (2) options for ventilation control, constant air volume (CAV) and variable air volume (VAV).

- To choose between CAV and VAV, you will need to take into consideration both operating duration and budget.

- To choose between CAV and VAV, you will need to take into consideration both operating duration and budget.

- A ducted fume hood has two (2) options for ventilation control, constant air volume (CAV) and variable air volume (VAV).

- What are the Operating costs and install of a fume hood?

- Operating Costs:

- Ductless fume hood = the majority of operating costs for a ductless fume hood will come from filter charges.

- Ducted fume hood = The cost of operating a ducted fume hood can be calculated as a function of how much air the blower is exhausting. Thus, the operating cost increases as a function of volume of air (DFM) being moved.

- Operating Costs:

- What accessories will you need for your fume hood?

- Fume hood accessories include base cabinets, light fixtures, airflow monitors, electrical outlets, cup sinks, and service fixtures for water, vacuum, or gas.

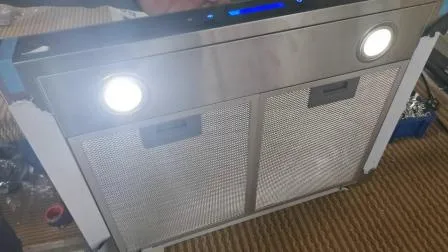

Prev: High Quality Range Hood Wall Mount 60/90cm T Shape Hoods Range Hood

Next: with CB/CE Ceritficate Wall Mount Strong Suction Power Range Hood

Our Contact